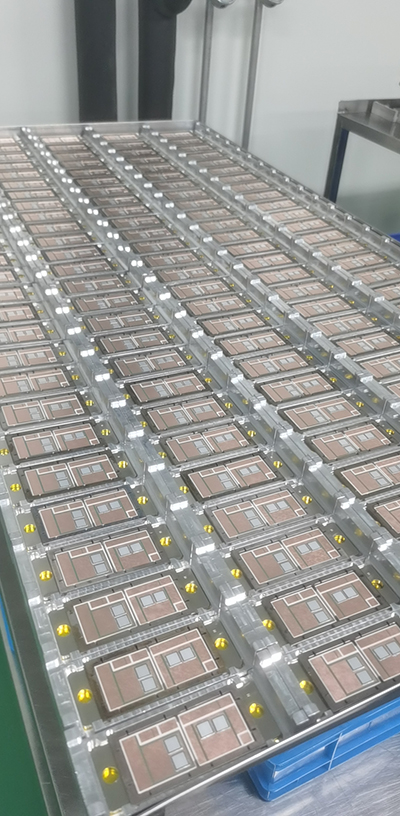

Sintering process in the chip of solid-state relays is of significant importance.

The use of sintering process in the chip of solid-state relays is of significant importance, primarily for the following reasons:

Product Quality and Reliability

The sintering process ensures high-quality and reliable chips. Through high-temperature sintering, the internal materials of the chip fuse effectively, forming a robust structure. This enhances the relay's resistance to vibration and impact, thereby improving stability and lifespan.

Electrical Performance

The sintering process contributes to consistent electrical performance within the chip. By controlling temperature and time during sintering, electronic components inside the chip can be evenly distributed, reducing variations in parameters such as resistance and capacitance. This improves the electrical performance of the relay, ensuring it operates reliably under various conditions.

Thermal Performance

Solid-state relays may generate heat during operation, and the sintering process helps enhance the chip's heat dissipation capabilities. This is crucial for the stability and reliability of the relay, especially during high-load and high-frequency operations.

Environmental Protection and Energy Efficiency

Sintering processes typically involve environmentally friendly, low-pollution techniques at high temperatures. Compared to some traditional manufacturing processes, sintering has a lower environmental impact. Additionally, improving the chip's electrical and thermal performance can reduce energy consumption, contributing to energy efficiency.

Therefore, choosing solid-state relays with chips manufactured using the sintering process ensures high-quality, reliability, and environmental suitability, making them well-suited for various industrial applications.

How solid state relays work? Testing SSR with multimeter and wiring.

How solid state relays work? Hoto to Test a solid state relay with multimeter? How to connect a SSR relay from PLC to heater? You will get an answer.

Read More

Mini Puck Solid-State Relay: A Compact and Reliable High-Efficiency Switching Solution

The GF1 solid state relay uses back-to-back thyristors for switching, which are more durable than traditional triacs.

Read More

Greegoo SCR Power Controller: The Ideal Choice for Industrial Applications

Three phase SCR power controller, phase shift thyristor regulator, IPM module 60A to 800A.

Read More

The Crucial Role of IGBT Modules in Power Electronics and Their Expanding Applications

The Key Role of IGBT Modules in Power Electronics and Modern Applications

Read More